NEW, COMFORTABLE, POWERFUL CONTROL: WELLDRIVE

The WD770 series of Honeywell WellDrive VFDs are new-generation drives designed for all HVAC and Pump applications, providing increased system efficiency, energy savings, and reduced costs.

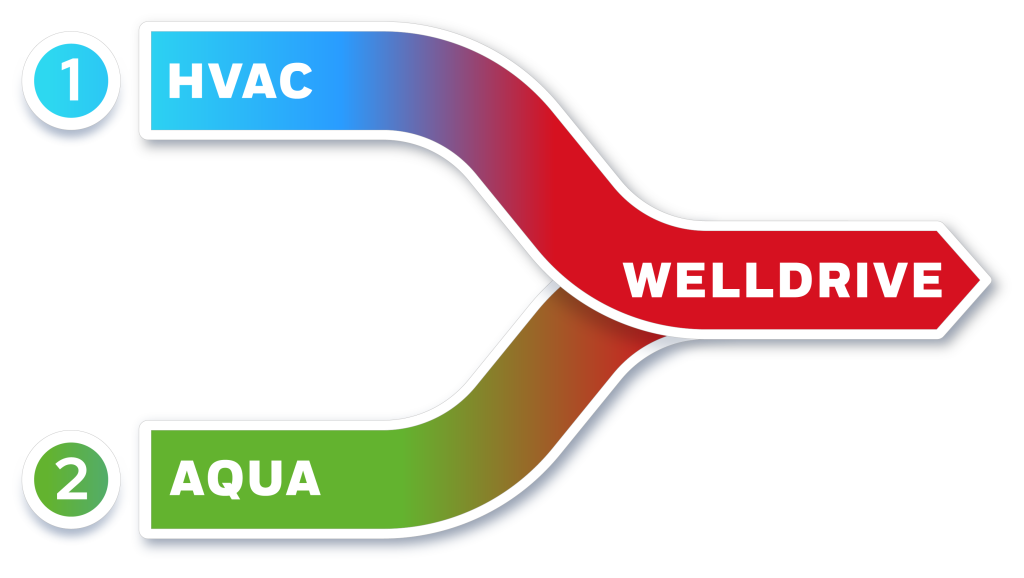

ALL YOUR NEEDS IN ONE PRODUCT

Designed for all Air Conditioning, Ventilation, Heating, Cooling, Water and WasteWater applications, the WD770 series drives are fully compatible with all AC motor types.

LEADING BRAND

WD770 drives, offered to you under Honeywell brand and extensive industry experience, provide you ease of use and flexibility with powerful hardware and software features.

TOTAL COST

Considering all the operating and maintenance costs over its lifetime, the WellDrive WD770 meets all of your expectations to minimize your costs with its quality and features.

ENERGY EFFICIENCY

It increases energy savings in your systems thanks to its special software in all applications where energy savings are achieved more. You will also save money thanks to its compatibility with high-efficiency motors.

COMFORT AND SAFETY

Thanks to its robust construction, the WD770 provides high comfort and safety in harsh environmental conditions for all HVAC and Water applications.

GENERAL APPLICATIONS PERFORMED WITH WD770

Fire Mode

PID Control

Sleep and Wakeup

PID AutoTune

Regeneration

Flying Start

Power Loss Right Through

Bypass

Sensors Support

Broken Belt Detection

Energy Saving Mode

Advnced Motor Control

Advanced Cascade Control

Pipe Filling Mode

Pipe Leakage Detection

Motor Pre-Heating

Real Time Clock

Pump Cleaning

Freeze Prevention

Dry Run Prevention

Communication Options

Advanced Protections

Detailed Failure Analysis

PC Software

ULTIMATE PERFORMANCE POWERFUL HARDWARE

Harmonic Filter

Built-in DC chokes reduce harmonic distortion in the grid in accordance with IEC 61000-3-12 standards. They also increase the lifetime of the DC link capacitors and therefore the efficiency of the drive.

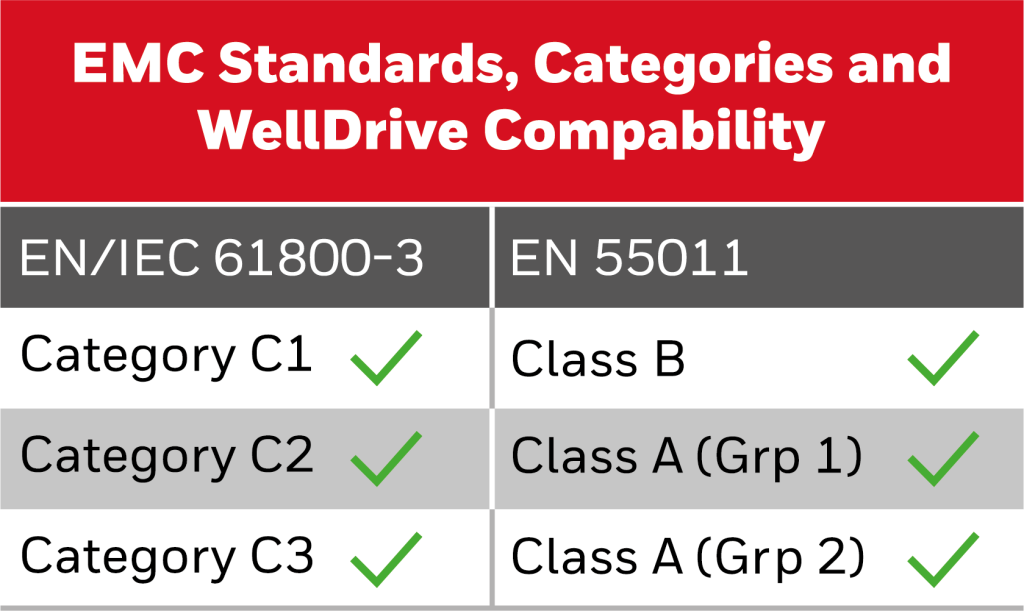

EMC Filter

WellDrive WD770 products have built-in EMC/RFI filters as standard. You can specify the standard or optional EMC filter type in accordance with the following standards.

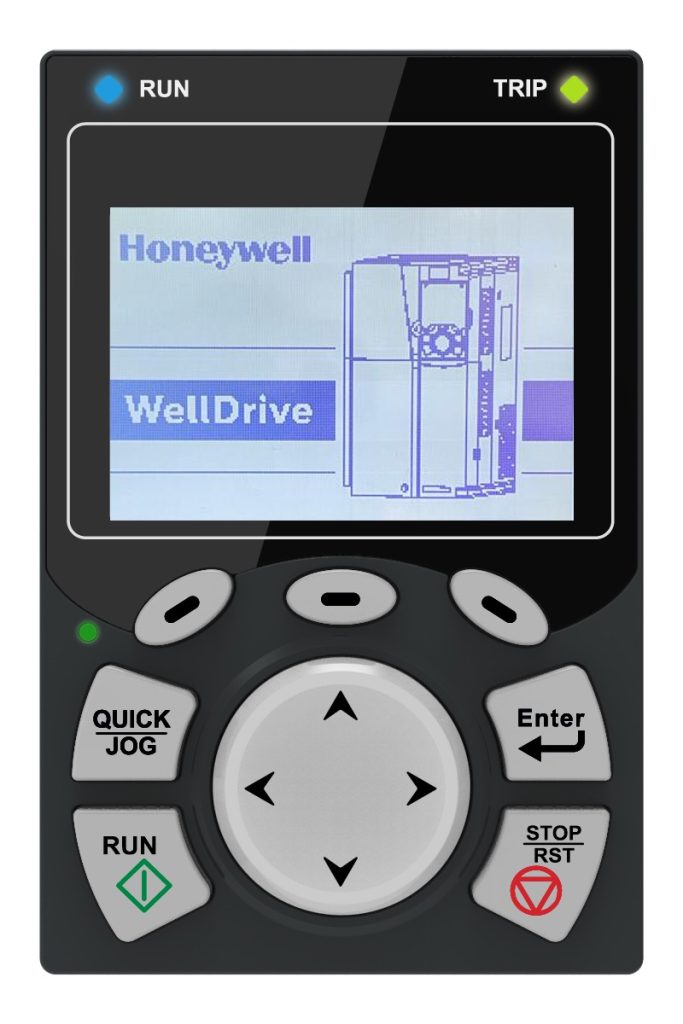

LCD Keypad

WellDrive offers great convenience in your commissioning processes with its easy-to-carry Graphic LCD Display Operator Panel, which includes multiple language options, a 5-line wide screen, Real-time clock, and many other features.

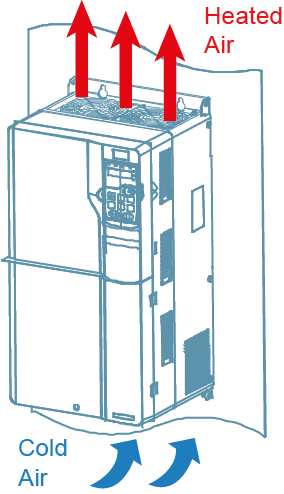

Independent Cooling

The WD770 can be expanded with optional I/O and various communication cards. This provides flexible compatibility for your system.

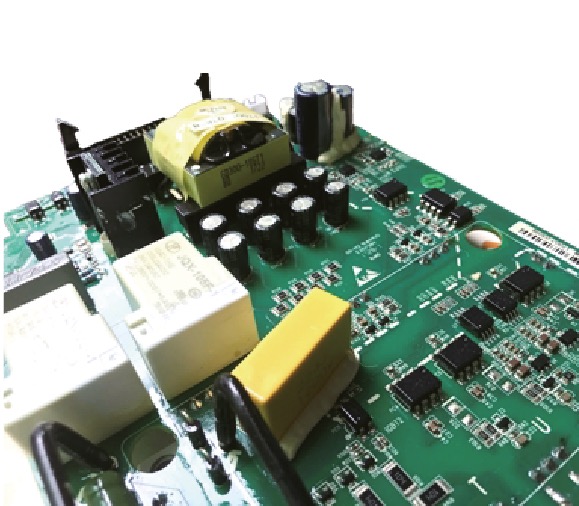

Coated PCBs

All electronic components within WellDrive are protected by varnish coating in accordance with IEC 60721-3-3 standards.

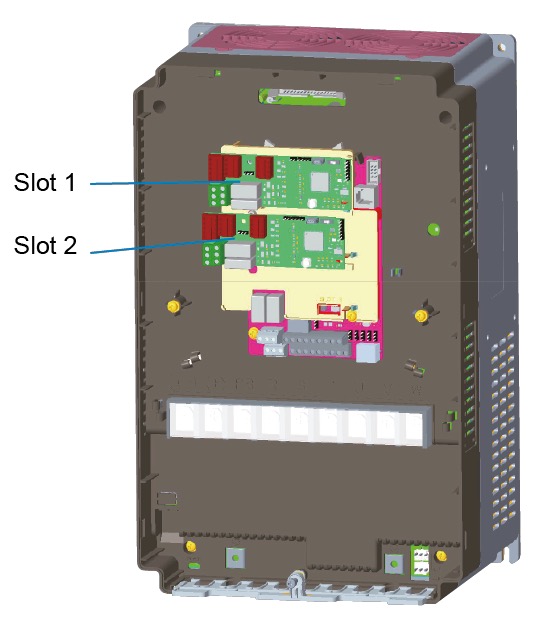

Expansion Modules

The WD770 can be expanded with optional I/O and various communication cards. This provides flexible compatibility for your system.

ADVANCED FEATURES FLEXIBLE SOFTWARE

In the event of a fire, it prevents the drive from ignoring all warning and error signals and taking itself into self-protection, thus ensuring continuous operation of the fan or pump.

It provides precise control of your process values such as Temperature, Pressure, Flow, Humidity without the need for an external controller. It also provides lower and upper limit level control.

It monitors the rotational speed of the motor to reduce the incoming pulse and improve restart efficiency and ensures that the motor resumes at the same speed at restart. In the event of a momentary power failure, the drive will continue to run automatically if this function and the start signal are active.

It ensures that the motor stops when there is no demand and saves energy. When the demand increases and the set values are reached, the motor is automatically restarted.

The driver provides DC current during power interruptions to increase the motor’s surface temperature and prevent motor failure caused by condensed water.

Thanks to the Auto-Tune feature, it reaches stable operation in your process quickly and easily by automatically optimizing the PID settings.

It allows a motor to be started from the mains when the failed drive cannot be used or when it is necessary to continue running at full speed.

One of the fans sharing the same duct is in a regeneration state under the influence of the others. The drive automatically keeps the output frequency under control to prevent over-voltage alarm and ensure stable operation of the machine.

Optimizes output power, ensuring optimum performance and lowest losses for low dynamic loads.

It can detect belt breakage in applications such as fans and compressors and can use this to stop the motor or send a warning signal.

The WD770 can control standard induction motors (IM), permanent magnet motors (PM), asynchronous and synchronous reluctance motors (SynRM) with high efficiency.

The WD770 supports AI/AO temperature measurement function for PT100, and KTY84 sensors. It also enables flexible operations such as differential pressure operations, along with arithmetic operations between analog inputs, in processes such as PID.

Up to 8 pumps can control multiple pumps. Real time clock support, synchronization and roaming master features are available.

In situations where it's necessary to fill pipes in a controlled manner, this feature allows pumps to start and stop slowly and smoothly. This helps prevent water-hammering, as well as damage to pipes and heads.

By continuously monitoring the pump operation, it detects dry running or leakage and prevents mechanical damage to the pump.

When the ambient temperature drops below a set threshold, the motor starts automatically to prevent the water from freezing and thus protect the pump.

It detects blockages that may occur in the pumps and ensures cleaning by systematically running forward and backward. This not only saves on mechanical maintenance but also keeps the pump’s efficiency at its highest level.

The WD770 has special protection functions for designated areas of use, safeguarding your motor, drive, and process.

When used with the LCD Panel, the driver can be programmed according to the time and date information, and malfunctions can be monitored.

It records the instantaneous operating values at the time of failure and enables analysis to uncover the causes and solutions.

It is free software with a user-friendly interface that allows you to easily program the WellDrive product family from your computer and access many of its functions.

In addition to Modbus RTU communication protocol, it provides full compatibility with your systems with various options such as BACnet, ProfiNET, and ProfiBus.

WELLDRIVE WD770 GENERAL FEATURES

| FUNCTIONS | FEATURES | |

| Control | Input Voltage | 3 Phase 380 – 480 Vac |

| Voltage Tolerence | -15% to +10% | |

| Input Frequency | 50 Hz or 60 Hz. (Max 47 – 63 Hz.) | |

| Control Mode | Advanced Scaler Control, Sensorless Vector Control | |

| Motor Type | IM, PM, SM, SYNRM | |

| Speed Ratio | Asynchronous Motor: 1:200, PM and Synchronous Motor: 1:20 | |

| Speed Control Accuracy | ±0.2% (Vector Control) | |

| Speed Fluctuation | ±0.3% (Vector Control) | |

| Torque Response | <20ms (Vector Control) | |

| Torque Control Accuracy | ±10% (Vector Control) | |

| Switching Frequency | 1 – 15 kHz (Standard 4 kHz) | |

| Overload Capability | 110% of rated current for 1 minute every 5 minutes. | |

| Operation | Frequency Settings | Analog, Digital inputs, Pulse input, Constant Speeds, Built-in PLC, PID Control, Communications |

| Operating Frequency | 0 – 400 Hz. | |

| Ramp Time | 0 – 3600 sn. | |

| Voltage Regulations | Automatically regulates the output voltage in response to mains fluctuations. | |

| Fault Protections | Overcurrent, Overvoltage, Undervoltage, Short Circuit, Overload, Overheat, Phase Loss etc. | |

| Special Features | Fire Mode, Cascade Control (8 pumps), PID with Sleep Mode, ByPass, Pump Cleaning, Dry Run, Regeneration Mode, Power Loss Ride Through, Flying Start, DC-Link, Pre-Heating, Freeze Protection, Pipe Filling etc. | |

| Flying Start | Used to implement shockless smooth starting for rotating motors. | |

| Interface | Analog Input | 2x Analog Inputs 1x 0 (2)~10V / 0 (4)~20mA and 1x -10 ~ +10V |

| Analog Output | 2x Analog Outputs: 0 (2)~10V/0 (4)~20mA | |

| Digital Type | PNP or NPN selectable. 24 Vdc. Impedance 3.3kΩ | |

| Digital Input | 5x Digital Inputs Max. 1kHz | |

| Digital Input | 1x High Frequency Pulse Input Max. 50kHz | |

| Digital Output | 1x Digital Output (Same features with the Relays) | |

| Relay Output | 2x Programmable Relay Output (NO and NC) (3A/AC250V, 1A/DC30V) | |

| Keypads | Standard LED keypad, Optional removable LCD keypad (RJ45 – Cat6) | |

| Communications | Standard Modbus RTU (RS485), Optional BACnet, ProfiBus, ProfiNET, CanOpen etc. | |

| Expansions | Two expansion slots. Expansion I/O cards, Communication options etc. | |

| Others | Mounting Types | Wall-Mounting (up to 250kW), Floor-Mounting (up to 132kW), Flange-Mounting (220kW~500kW) |

| EMC Filter | Built-in class C3 according to EN/IEC 61800-3, optional class C2 | |

| Harmonic Filter | Built-in DC choke according to IEC 61000-3-12 standard | |

| Operating Temperature | -10°C ~+50°C | |

| IP Protection Class | IP20 for below 200 kW, IP00 for 200 kW and above. | |

| Coated PCBs | 2nd degree according to IEC60721-3-3 standards | |

| Power Factor (Cos ɸ ) | > 0.98 | |

| Altitude | 100% of rated current for <=1000m. 1% derating for every 100 meters between 1000-3000m. | |

| Relative Humidity | 5% – 95% (IEC 721-3-3; Class 3K3 (non-condensing) (during operation) | |

| Galvanic Insulation | Standard (PELV) | |

| Efficiency | 0,98 | |

| Cooling Method | 1.5kW: Natural cooling, 2.2kW and above: Fan cooling. Independent cooling channel | |

| Accessories | WDM-IO-1 | IO Module (4xDI, 1xDO, 2xRO, 1xAI, 1xAO) |

| WDM-RO-1 | Relay Module (6xRO, 2xDI) | |

| WDM-BC-1 | BACnet Communication Module | |

| WDM-PB-1 | ProfiBus-DP Communication Module | |

| WDM-PN-1 | ProfiNET Communication Module | |

| WDM-MT-1 | Modbus-TCP Communication Module | |

| WDM-CO-1 | CANopen Communication (for Master-Slave applications) | |

| WDM-24-1 | 24Vdc External Power Supply Input Terminal | |

| WDM-BOP-1 | LED Keypad | |

| WDM-LCD-1 | LCD Keypad | |

| WDM-EXT-1 | Keypad Mounting Kit | |

| WDM-MRL-1 | DIN Rail Mounting Kit | |

WELLDRIVE WD770 TECHNICAL DATA

| Drive Power | Product Reference | Rated Current | Frame Type | Dimensions (mm.) WxHxD | Net Weight |

| 0.75 kW | WD770-3A7-4 | 3.7 A | F1 | 89 x 231 x 193 | 2 Kg |

| 1.5 kW | WD770-3A7-4 | 3.7 A | |||

| 2.2 kW | WD770-5A0-4 | 5.0 A | |||

| 3 kW | WD770-9A5-4 | 9.5 A | |||

| 4 kW | WD770-9A5-4 | 9.5 A | |||

| 5.5 kW | WD770-13A-4 | 13 A | F2 | 89 x 259 x 211.5 | 2.4 Kg |

| 7.5 kW | WD770-17A-4 | 17 A | |||

| 11 kW | WD770-25A-4 | 25 A | F3 | 145 x 280 x 207 | 5 Kg |

| 15 kW | WD770-32A-4 | 32 A | |||

| 18.5 kW | WD770-38A-4 | 38 A | F4 | 169 x 320 x 214 | 6.4 Kg |

| 22 kW | WD770-45A-4 | 45 A | |||

| 30 kW | WD770-60A-4 | 60 A | F5 | 266 x 371 x 208 | 11 Kg |

| 37 kW | WD770-75A-4 | 75 A | |||

| 45 kW | WD770-92A-4 | 92 A | F6 | 316 x 430 x 223 | 16 Kg |

| 55 kW | WD770-115A-4 | 115 A | F7 | 352 x 580 x 258 | 24 Kg |

| 75 kW | WD770-150A-4 | 150 A | |||

| 90 kW | WD770-180A-4 | 180 A | |||

| 110 kW | WD770-215A-4 | 215 A | F8 | 338 x 554 x 338.3 | 43 Kg |

| 132 kW | WD770-250A-4 | 250 A | |||

| 160 kW | WD770-305A-4 | 305 A | F9 | 338 x 825 x 398.3 | 78 Kg |

| 185 kW | WD770-330A-4 | 330 A | |||

| 200 kW | WD770-380A-4 | 380 A | |||

| 220 kW | WD770-425A-4 | 425 A | F10 | 303 x 1108 x 480 | 103 Kg |

| 250 kW | WD770-460A-4 | 460 A | |||

| 280 kW | WD770-530A-4 | 530 A | F11 | 330 x 1288 x 544 | 121 Kg |

| 315 kW | WD770-600A-4 | 600 A | |||

| 355 kW | WD770-650A-4 | 650 A | |||

| 400 kW | WD770-720A-4 | 720 A | F12 | 330 x 1398 x 544 | 173 Kg |

| 450 kW | WD770-820A-4 | 820 A | |||

| 500 kW | WD770-860A-4 | 860 A |

(*) You may also contact our expert team for higher power and other voltage options.

(*) The WD770 has a loadability of 110% for 1 minute every 5 minutes over its rated current rating.